Tool Design of Injection Molds

Atlas Precision, Inc. has a 25-year track record and a reputation for building some of the fastest cycling -tooling in the plastics industry. Our reputation was built by developing a tool engineering group that understands plastics manufacturing. Our engineers begin a tool design only when they understand the manufacturing requirements and constraints provided by the customer. Every tool design takes into consideration the following:

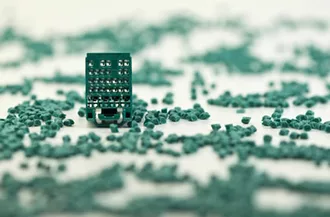

- The type of plastics material and crystalline or amorphous properties of the material.

- Material flow considerations including fill, pack and aesthetic considerations.

- The type colorant and fillers that will be processed so that gasses and residue produced can be successfully managed to optimize speed and minimize maintenance.

More Products and Services

Atlas Precision Plastics offers a variety of products and services. We can assist you from product design to mold flow and packaging.