Construction of Injection Molds

Atlas Precision, Inc. tool construction meets the demands of the particular application. We keep things simple: simple to assemble, disassemble  and simple to maintain. Atlas Precision, Inc. high-cavitation tooling consistently exceeds customer expectations for trouble-free performance and longevity. Please note:

and simple to maintain. Atlas Precision, Inc. high-cavitation tooling consistently exceeds customer expectations for trouble-free performance and longevity. Please note:

- Structural Integrity

- Modulus of base plates, rails and support columns is carefully engineered to maintain a flat parting line at cycle speeds, loads and temperatures.

- Compression, tension and bending calculations are made and tool steels, hardness, and surface coatings are expertly selected.

- Ejector plates are designed to carry injection as well as ejection loads

- Mechanical Function

- Safety and simplicity are first and foremost considerations.

- Horn pins are designed with removable caps for easy maintenance.

- Every mechanical action component is designed with handling and maintenance in mind.

- Ejector pins are shoulder guided in the retainer plate and vent relieved.

- Accelerated ejection is always used to free parts from lifters.

- Thermal Expansion

- Steel expansion is calculated at cycle-speed temperatures to prevent premature component wear.

- Cooling

- Tool and component temperature control is maintained in each segment of the tool at cycle speed.

- Water volumes in each cooling segment are calculated to maintain uniform temperature profile and achieve maximum temperature removal rate.

- Venting

- Active vent pins are used when applicable.

- Direction of gasses to outside and away from internal components.

- Large leader pin vents are used to facilitate cleaning.

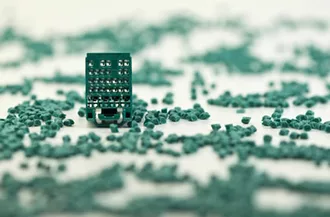

- Materials

- Steels and coatings are selected to optimize tool life and enhance heat exchange.

- Non-ferrous metals and specialty materials are used to speed or retard the removal of temperature when appropriate.

- Hot Runner Systems

- Plug boxes are designed with clearance and handling considerations in mind.

- Maintenance ease, service considerations and next day component availability are required to be demonstrated by the hot runner supplier before system selection is made.

- Top Half and Stack Mold center sections must be approved by Atlas designers and satisfy Atlas safety and maintenance requirements before system selection.

- Mold Straps and handling instructions are provided with every tool.

- Identification and nameplates are installed on every tool.

- Water line identification and sequence and volume requirements are indicated.

- Electrical wire schematics and wattage requirements are indicated when applicable.

- Safety

- Mold Straps and handling instructions are provided with every tool.

- Identification and nameplates are installed on every tool.

- Water line identification and sequence and volume requirements are indicated.

- Electrical wire schematics and wattage requirements are indicated when applicable.

More Products and Services

Atlas Precision Plastics offers a variety of products and services. We can assist you from product design to mold flow and packaging.